Diamond Plate Sheets and Smooth Metal Trim

(18 results)

Diamond Plate Sheets, Wall Panels, and Tiles-A422

Smooth Metal Sheets, Wall Panels and Tiles-A838

Stainless Steel Corner Guards-A674

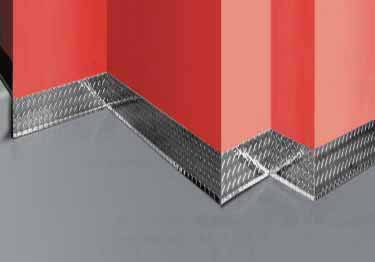

Diamond Plate Wall Corner Guards-A417

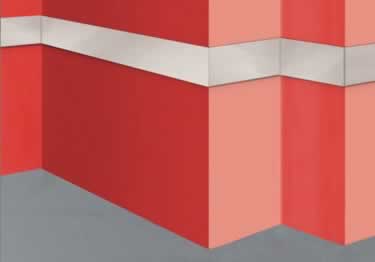

Smooth Metal Wall Base Molding-A531

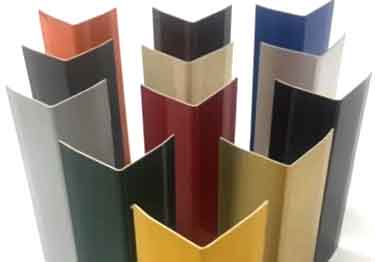

Colored Metal Corner Guards-A443

Aluminum Corner Guards-A675

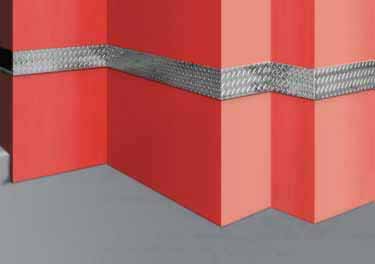

Diamond Plate Chair Rail -A424

Smooth Metal Chair Rail -A536

Pegboards Options

Magnetic Panels

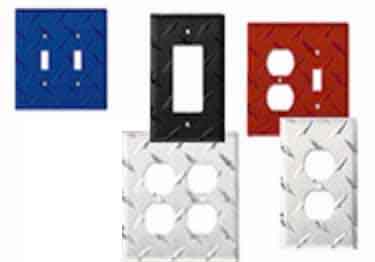

Diamond Plate Switch Covers-A418

Diamond Plate Parking Spot-A1504

Liquid Nails | Polyurethane Construction Adhesive LN-950-A419

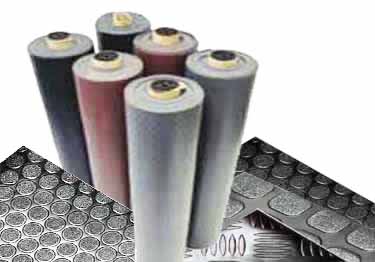

Colored Vinyl Flooring Rolls-A731

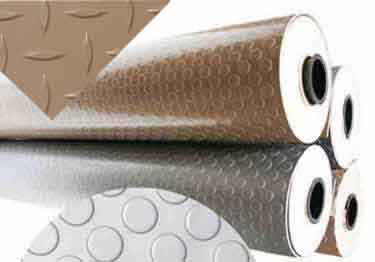

Vinyl Metallic Color Flooring Rolls-A732

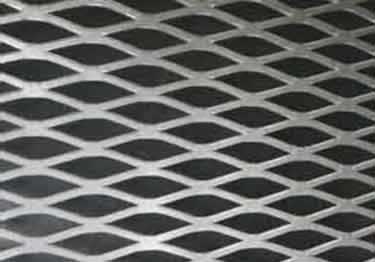

Expanded Metal Flattened Sheets | Aluminum-A446

Recently Viewed Products

Utility Crossover Cable Protector-A1032

Protects cables & hoses while providing safe passage for vehicles. Great for maintenance/emergency situations. On sale now, 17% off regular price. Starting at $895.23

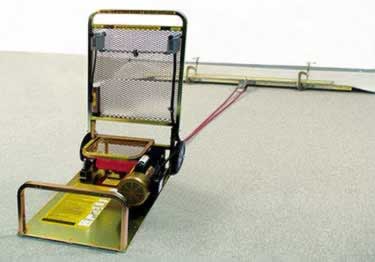

Carpet Puller by National Equipment NCE71-A4698

Pull glued-down carpet with ease from any floor surface with our commercial grade, Powered Carpet Remover. On sale now, 10% off regular price. Starting at $6,570.23

Schluter®-DILEX-KSN - Surface Joint Profile-A4727

Allow movement, reduce stress, & protect tile edges in large tiled areas. Stainless steel or aluminum anchoring legs. On sale now, 10% off regular price. Starting at $161.73

Johnsonite | Tarkett Vinyl Wall Base-A505

Clean finish around the perimeter of your room. Commercial grade 1/8" vinyl. 120 ft rolls&4 ft. strips box/30. On sale now, 20% off regular price. Starting at $32.41

Diamond Plate Sheets and Smooth Metal Trim Information

Wally and Floora Say:

Wally Says:

Hey Floora, Diamond plate sheets and trim bring a rugged, industrial aesthetic along with practical durability to any space. These materials are ideal for areas that demand high durability and slip resistance. When selecting diamond plate for your project, consider these essential factors:

- Materials: Diamond plate is typically made from aluminum or steel. Aluminum is lighter and resistant to corrosion, making it suitable for indoor and outdoor applications. Steel is heavier and incredibly durable, ideal for high-traffic areas or where greater strength is needed.

- Texture: The raised diamond pattern provides superior grip, reducing the risk of slips and falls. This makes it perfect for flooring, stair treads, or ramp surfaces.

- Thickness: Choose the thickness based on the level of impact and wear the area will receive. Thicker plates withstand more abuse and are preferable in industrial environments.

- Finish: Diamond plates can be polished, powder-coated, or left in a natural matte finish, allowing for customization according to the aesthetic of your space.

Buying Tip: When selecting diamond plate for areas prone to wear or where safety is crucial, consider complementing your purchase with additional safety features.

Floora Says:

Thank you Wally, installing diamond plate correctly is crucial for maximizing its benefits. Here’s how to ensure a flawless installation:

- Preparation: Ensure the surface area is clean and even. Any debris or unevenness can affect the installation integrity of the diamond plate.

- Cutting to Size: Use appropriate tools such as a metal saw for steel or a standard circular saw with a blade suitable for aluminum. Always measure twice to ensure your cuts are precise.

- Installation: Secure the diamond plate using screws or bolts for heavy-duty applications. For lighter applications, strong adhesives may suffice.

- Maintenance: Regular cleaning with mild soap and water will maintain the appearance and functionality of the diamond plate. Avoid harsh chemicals that might degrade the material over time.

Buying Tip: To keep your diamond plate looking great and performing well, consider professional-grade installation tools and maintenance products. Flooring tools are essential for precise cuts and secure fitting, while adhesives ensure your diamond plate stays firmly in place even under heavy use.