In the ever-evolving world of construction and infrastructure, the integrity of structures often depends on small but crucial components. One such element is the expansion joint, a vital feature that accommodates the natural movement of materials caused by temperature fluctuations, seismic activity, and mechanical stress. Whether in buildings, bridges, pipelines, or HVAC systems, expansion joints play an indispensable role in preventing cracks, structural fatigue, and long-term damage.

According to Wikipedia, an expansion joint is a structural separation designed to safely absorb the expansion and contraction of different building materials. These joints are essential for maintaining the integrity of structures exposed to varying environmental conditions.

This comprehensive guide explores what expansion joints are, how they work, and why they are critical in various applications.

What Are Expansion Joints?

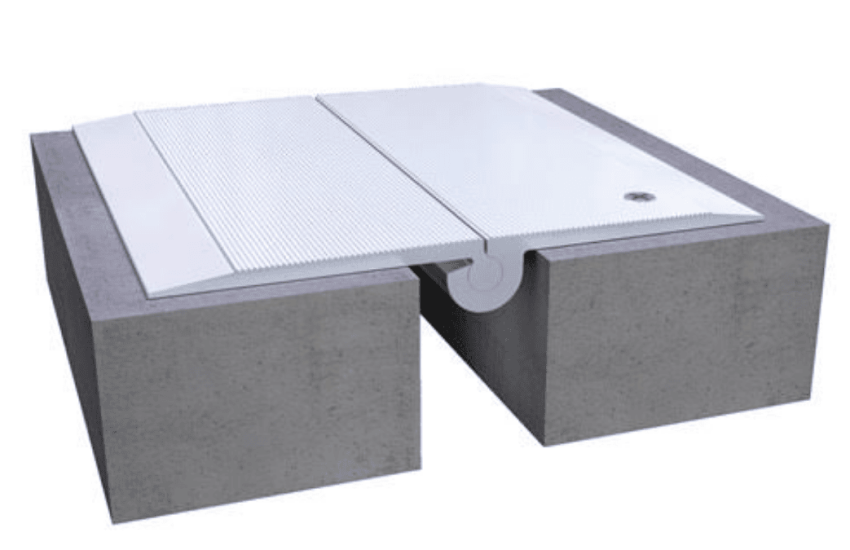

An expansion joint is an engineered separation between sections of a structure that allows for movement and flexibility without compromising stability. As materials expand and contract due to changes in temperature, humidity, or load, these joints absorb the resulting stresses. Without them, buildings, roads, and pipelines would be far more susceptible to cracking, buckling, or even catastrophic failure.

Fundamentally, expansion joints provide the space necessary for structural components to shift as needed while maintaining their overall cohesion and integrity. They are essential in both small-scale construction and large infrastructure projects.

Types of Expansion Joints

There are several types of expansion joints, each tailored to a specific structural need or industry. Choosing the right type depends on the application, materials used, and environmental factors at play.

Structural Expansion Joints

These joints are widely used in buildings, bridges, and large civil engineering projects. Structural expansion joint covers help protect these joints from wear while maintaining a clean, finished appearance in interior and exterior spaces.

Pipeline Expansion Joints

In piping systems, pipeline expansion joints are critical for managing the thermal expansion of pipes transporting fluids and gases. They are commonly installed in water supply systems, chemical processing plants, and oil refineries. These joints absorb vibration and axial movement, reducing stress on pipelines and preventing leaks or ruptures.

Railway Expansion Joints

Railway tracks are constantly exposed to temperature changes, causing them to expand and contract throughout the day. Railway expansion joints compensate for this movement, maintaining track alignment and ensuring safe, efficient train operation. They are particularly important in regions with extreme weather variations.

HVAC Duct Expansion Joints

HVAC systems require duct expansion joints to accommodate the expansion and contraction of metal ductwork as air temperatures fluctuate. These joints also help reduce noise and vibration, ensuring smoother operation and longer equipment life. Properly installed expansion joints can prevent damage to ducts and improve energy efficiency.

Road and Bridge Expansion Joints

Roads and bridges undergo constant stress from traffic loads, temperature shifts, and environmental factors. Expansion joints installed in these structures enable movement without causing cracks or gaps in the pavement. They play a critical role in the longevity and safety of highways and bridge decks by preventing surface deterioration and structural weakness.

How Expansion Joints Work

The principle behind expansion joints is simple but effective. They are designed to absorb movement by providing a flexible, controlled gap between structural elements. To protect these gaps and ensure a safe, finished surface, expansion joint covers are often installed in floors, walls, and ceilings of commercial and industrial buildings.

In concrete construction, for example, joints are often filled with compressible materials like rubber or foam, allowing the concrete slabs to expand without pushing against each other. In pipelines, metallic bellows or flexible couplings absorb axial expansion while maintaining a sealed connection. The precise engineering behind each joint ensures that structures can move without causing damage to themselves or nearby components.

Common Materials Used in Expansion Joints

The materials selected for expansion joints are critical to their performance and longevity. Several factors influence the choice, including temperature range, chemical exposure, and load-bearing requirements.

Rubber is a popular material due to its flexibility and resistance to weathering. Neoprene and EPDM rubber are commonly used in road and bridge joints because they withstand harsh environments and high levels of movement. Metal expansion joints, typically made from stainless steel or aluminum, are used in industrial applications requiring high strength and corrosion resistance. In less demanding environments, materials such as cork, foam, or bituminous compounds offer an economical solution.

Each material is chosen with its specific function in mind, ensuring that the expansion joint performs reliably over its intended service life.

Expansion Joint Caulking

Expansion joints are essential in construction, allowing structures to expand and contract without causing damage. However, in the field, many expansion joints are not visually appealing, making caulking an important step in maintaining both function and aesthetics.

When selecting a commercial caulk for expansion joints, it’s crucial to ensure compatibility with the materials used. Whether for concrete, metal, or standing seam joints, the right caulk must meet specifications that allow it to expand within the joint’s movement restrictions. Engineers typically review and approve the caulking materials to confirm they provide the necessary flexibility and durability.

Beyond sealing gaps, caulking plays a vital role in keeping expansion joints free of debris, ensuring they perform as intended. Properly applied caulk enhances the joint’s longevity and effectiveness, preventing structural issues over time.

Applications of Expansion Joints in Various Industries

Expansion joints are used across a wide range of industries, each with unique requirements.

In the construction industry, they are essential in high-rise buildings, parking structures, and stadiums to manage thermal expansion and seismic activity. Infrastructure projects, such as roads and bridges, rely on expansion joints to prevent cracking and deterioration under heavy loads and temperature changes.

In energy and utilities, pipeline expansion joints are used in oil refineries, water treatment plants, and power generation facilities to protect pipes from pressure fluctuations and thermal expansion. Railway networks use expansion joints to maintain the integrity of their tracks, while HVAC systems employ them to minimize noise and accommodate ductwork expansion.

Advantages of Using Expansion Joints

Incorporating expansion joints into a project offers numerous benefits. They extend the lifespan of structures by reducing stress and preventing cracks. Expansion joints also enhance safety by maintaining the structural integrity of bridges, buildings, and pipelines. Furthermore, they reduce maintenance costs by preventing premature damage and minimizing the need for repairs.

In mechanical systems, they absorb vibration and reduce noise, improving system efficiency and prolonging the life of equipment. Ultimately, expansion joints represent a cost-effective solution that protects investments in construction and infrastructure.

Factors to Consider When Choosing Expansion Joints

Selecting the right expansion joint requires careful consideration of several factors. The type of structure, environmental conditions, expected movement, and load capacity all play a role in the decision-making process.

For example, bridges exposed to extreme temperature fluctuations need joints that can handle large amounts of expansion and contraction. Industrial pipelines transporting corrosive chemicals require joints made from materials resistant to chemical attack. Working with experienced engineers and manufacturers can help ensure the optimal choice for each application.

Significant Impact on Structural Performance

Expansion joints may be small components, but their impact on structural performance is significant. From preventing cracks in concrete slabs to ensuring the safe operation of pipelines and railways, these joints are essential in modern construction and infrastructure. Understanding the types, applications, and materials used in expansion joints enables project managers, engineers, and contractors to make informed decisions that enhance the durability, safety, and efficiency of their projects.

Incorporating high-quality expansion joints and expansion joint covers, along with following best practices in design, installation, and maintenance, is key to ensuring long-term success in any construction or infrastructure endeavor.