During the construction of a home, office space, warehouse, and most building applications where a wall meets making a corner, the use of wall corner guards are incorporated. The basic use in carpentry is a thin, metal strip adhered with drywall mud, to create a finished corner. While the carpenter uses nails that are driven into pre-drilled slots, these are concealed by the mud, this is later painted and unnoticeable to the naked eye. The use of self-adhesive guards and liquid nail adhesive are also utilized.

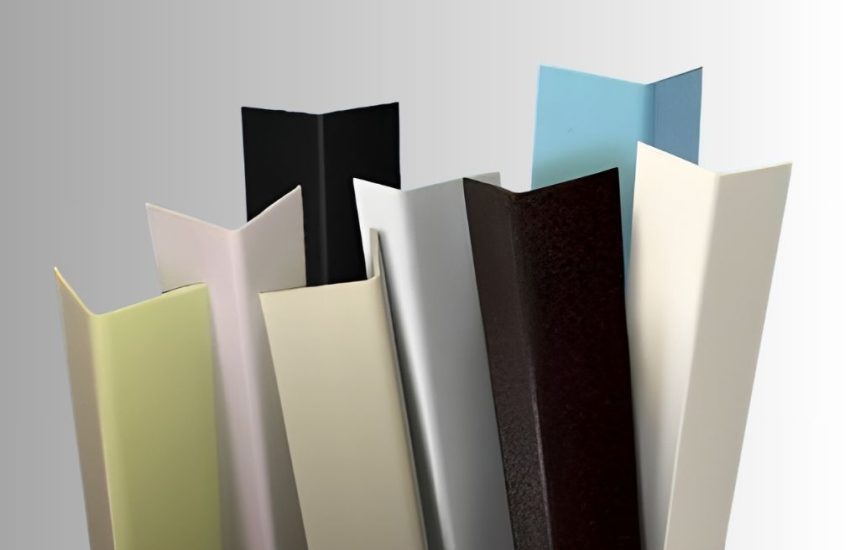

The wall corner guards have evolved over the years, and their practical and decorative uses enhance any living space. Both practical and functional, they help to maintain the shape of the vertical point and protect the edge from damage resulting from any contact by man or machine. They come in a variety of materials and designs, allowing them to blend seamlessly with different interiors or stand out as a bold design element.

In essence, that is their primary purpose in residential construction to protect the corner bead.

Around the office, wall corner guards are used in a variety of ways; protecting the interior walls edge, and also as safety features when used to cover a desktop or cabinet edge. In this environment, the corner guards can also be customized in different textures and finishes, such as matte, glossy, or metallic, to match the office’s overall aesthetic. Available in a variety of sizes and textures, the theme of an interior design is complimented with ease.

Not overlooking the warehousing workplace, the wall corner guards also add protection, not only to the surface areas, but for the employee as well. Sharp edges of tier levels, obscured corners, and other potential hazards can become less ominous with rubber guards applied. Installing rubber or impact-resistant guards can reduce accidents, improving workplace safety standards. From the inner office, to the shipping docks, the use of protective guards pays for themselves over and again.

Common Materials for Wall Corner Guards

Wall corner guards can be made from a variety of materials, each offering different benefits in terms of durability, aesthetics, and cost. Here’s a breakdown of some common materials:

Metal

Often used in heavy-duty applications, metal corner guards (like stainless steel, aluminum, and brass) provide excellent durability and resistance to impact. They are suitable for high-traffic areas or places susceptible to heavy wear and tear. For added design appeal, metal corner guards can come in brushed, polished, or powder-coated finishes. They offer a range of benefits that make them a strong option for both residential and commercial spaces — as detailed in our overview of metal corner guards.

More of a visual learner? Watch how corner guards with aluminum retainer are installed!

Plastic

Including materials like PVC and vinyl, plastic corner guards are versatile, cost-effective, and easy to install. They offer good protection against scuffs and are available in a range of colors to match various decor styles. Plastic guards are particularly popular in hospitals and schools due to their affordability and ease of replacement.

Rubber

Known for their shock-absorbing qualities, rubber corner guards are ideal for environments where bump protection is crucial, such as garages and warehouses. They’re also beneficial in child-centric environments due to their cushioning effect.

Wood

Wood corner guards, often made from faux wood, blend well with traditional or luxurious interiors and are typically used for their visual appeal rather than for high-level protection. They can be customized to match existing woodwork. However, wood guards require maintenance and are best used in low-traffic residential settings.

Clear vs. Colored Corner Guards

Clear corner guards excel at blending into their surroundings, maintaining the original aesthetics of a space. They are less noticeable, ideal for preserving the look of walls or wallpaper. While they protect against scratches and minor impacts, the primary advantage of installing clear corner guards is their ability to remain discreet, suitable for areas with moderate activity.

Colored corner guards, conversely, provide both protection and aesthetic enhancement. Available in various colors, they can either match or contrast with existing wall colors, effectively serving as design elements. Beyond wall protection, these guards use color coding to facilitate navigation and access control, adding functional value through visual cues.

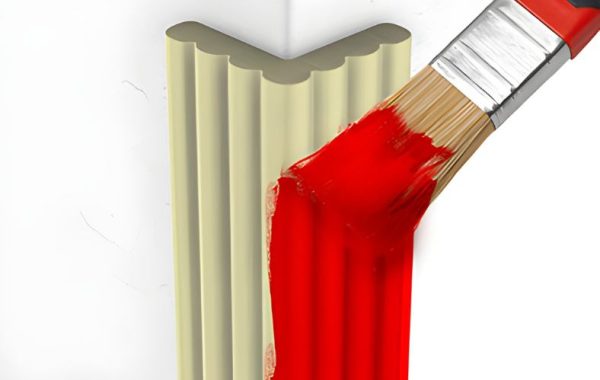

Paintable vs Non-Paintable Corner Guards

Paintable corner guards are a versatile choice for those who want a seamless integration with their existing wall colors or designs. Made typically from materials like bare metal, wood, or certain plastics that accept paint, these guards can be coated to match any color scheme, making them almost invisible against the walls. Non-paintable corner guards, on the other hand, are ready to use and also come in a variety of pre-finished colors and materials. These types of guards are ideal for areas where durability and ease of maintenance are more important than a perfect visual match. For example, stainless steel and rubber corner guards do not require painting and are designed for long-term durability with minimal upkeep.

How to Choose the Right Corner Guard

It’s important to consider both the type of surface and the level of impact it will face. Different materials are better suited for different surfaces, such as drywall, brick, or wood, and the cleanliness of the surface is crucial for proper adhesion. If the corner is in a high-traffic area, you might need a more durable material that can handle repeated impacts from objects like carts or wheelchairs. This ensures that not only are your walls protected, but also your customers, employees, and guests are safe from sharp corners.

Installation method is another crucial factor—some corner guards require drilling and screws for a secure fit, while others use adhesive backing for a quicker application. Be sure to follow manufacturer recommendations to ensure a long-lasting and effective installation.

Aesthetic considerations and cost are also key factors in choosing corner guards. They come in various materials and colors, allowing you to match them with the existing décor without making them look out of place. Whether you’re looking for something that blends in or stands out, there’s a range of options to suit every taste and budget. This flexibility means you can protect your space effectively while keeping it looking great.

From ground-up construction to the matching of color templates for inner-office design, the practical uses of wall corner guards have met or exceeded the demands of a carpenter’s level to the corporate level, and all those in between. A functional design to maintain the original edge of any corner or end-wall application, the wall corner guard provides the protection and durability as no other product found on the market can provide.

Maximizing ROI with Corner Guards

Investing in wall corner guards can significantly reduce long-term repair costs. By preventing damage in high-traffic areas, they ensure walls stay in top condition. In commercial buildings, regularly damaged walls can lead to thousands of dollars in maintenance costs annually, making corner guards a cost-effective preventative measure. Curious about the numbers? Check out our detailed analysis of the ROI of installing corner guards versus repeated wall repairs.

Curious about the ROI of corner guards, read our guide on how to determine if it’s worth it to install corner guards.