Expansion Joint Covers

(24 results)

InPro® 806 Floor Expansion Joint Covers-A140

InPro® 801 Floor Expansion Joint Covers-A138

InPro® 808 Floor Expansion Joint Covers-A141

CS Acrovyn PC2G & PCS2G Floor Expansion Joint Covers-A105

CS Acrovyn RFB & RFWB Restofit™ Expansion Joint Covers-A108

INPRO 807 Floor Expansion Joint Covers-A180

Wall and Floor Expansion Joint Seal InPro AR Series-A191

CS Acrovyn RFD & RFDW Restofit™ Expansion Joint Covers-A106

InPro 734 Floor Expansion Joint Covers-A178

CS Acrovyn RFC & RFCW Restofit™ Expansion Joint Covers-A107

Expansion Joint Cover CS Acrovyn GFST and GFSTW-A192

CS Acrovyn RFA & RFAW Restofit™ Expansion Joint Covers-A109

InPro® 804 Floor Expansion Joint Covers-A139

CS Acrovyn Expansion Joint Covers ZB-A194

Expansion Joint Covers CS Acrovyn GFPS/GFPSW Series-A190

Expansion Joint Covers for Concrete CS ZBSM-A198

Floor Expansion Joint Covers CS Acrovyn GFS and GFSW-A189

InPro® 802 Floor Expansion Joint Covers-A179

Outdoor Expansion Joint Covers by CS Acrovyn HB-A193

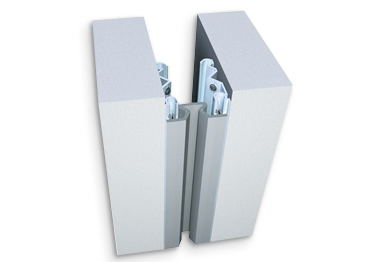

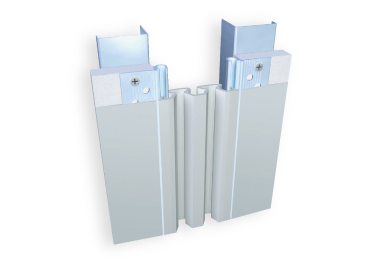

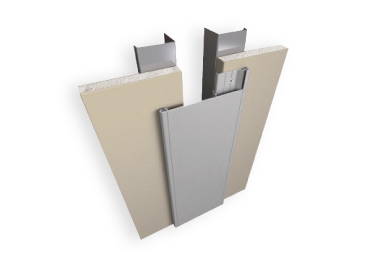

Wall to Wall Expansion Joint Covers InPro 611 Series-A996

Expansion Joint Covers for Corner | Wall | Ceiling InPro 113 Series-A199

Expansion Joint Covers for Corner | Wall | Ceiling InPro 114 Series-A997

Expansion Joint Covers for Corner | Wall | Ceiling InPro 116 Series-A998

Expansion Joint Covers for Corner | Wall | Ceiling InPro 811 Series-A999

Expansion Joint Covers Information

Expansion Joint Covers

Wally and Floora:

Wally Says:

Floora, did you know that floor expansion joint covers are the unsung heroes of construction? These covers provide a seamless and durable solution for accommodating movement in flooring systems, protecting against damage caused by temperature changes, vibrations, or heavy traffic. Perfect for architects, contractors, and DIY enthusiasts, our floor expansion joint covers ensure both functionality and aesthetic appeal.

Here's what to consider when choosing floor expansion joint covers for your project:

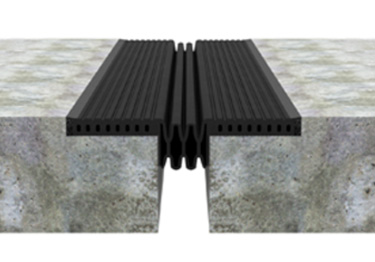

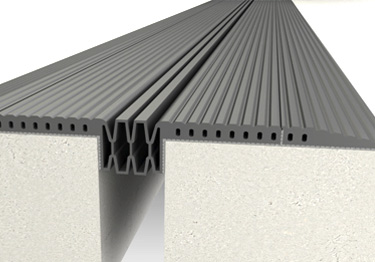

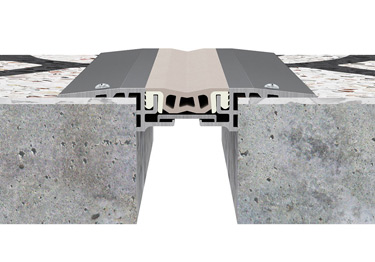

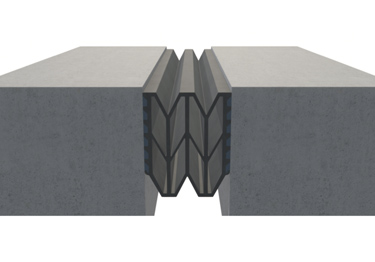

- Material and Design: Select from aluminum, stainless steel, or flexible rubber options, each tailored to different flooring types and movement requirements.

- Size and Movement Capacity: Ensure the cover accommodates the expected range of expansion and contraction without compromising stability.

- Application and Installation: From commercial buildings to hospitals and retail spaces, choose a cover designed for your flooring type and traffic load. Easy installation and compatibility with adjacent flooring materials are key.

Buying Tip: For areas with high foot traffic or heavy machinery, select floor expansion joint covers with enhanced load-bearing capacity and slip resistance.

Floora Says:

Thank you, Wally! Installing floor expansion joint covers correctly is essential for maintaining both the structural integrity and appearance of your flooring system. Here are a few tips:

- Preparation: Ensure the installation area is clean, level, and properly measured. Precision is critical for smooth integration with your flooring.

- Installation Method: Follow the manufacturer's instructions carefully. Some covers may require recessed installation, while others are surface-mounted for ease.

- Sealing: Proper sealing is vital to prevent debris or moisture from compromising the floor system.

- Inspection and Maintenance: Regularly inspect the covers for wear and tear, especially in high-traffic areas. Replace any damaged components promptly to avoid disruptions.

Buying Tip: Always keep a few spare floor expansion joint covers on hand for quick replacements or repairs. Explore our extensive collection of covers designed for various flooring systems and environments.